The Last Crane

Each new day on the Capitol Complex Project brings a flurry of activity carefully choreographed for maximum safety and efficiency. And while most of us think of construction as happening on the ground, there is also plenty of action taking place in the sky. At the height of the exterior construction phase, six massive tower cranes, strategically located throughout the site, stayed busy moving thousands of pounds of construction material from delivery points to where the work was happening. This past weekend, the last crane onsite was dismantled and removed.

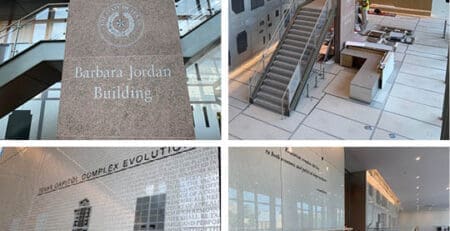

This is a significant construction milestone that represents the near completion of the exterior phase of the project and a shift in focus to the interiors of these magnificent buildings. Here’s a brief tribute to the role of cranes on this iconic construction project.

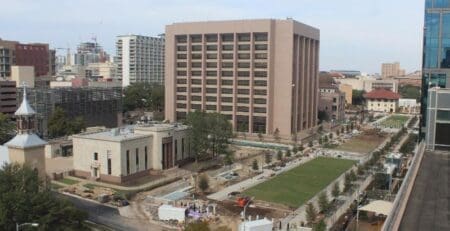

A Bird’s Eye View

The Capitol Complex Project cranes ranged in size from the smallest at approximately 168 feet to the largest at 258 feet (or about three-fourths as tall as the Texas State Capitol Building). The 1801 Congress building had two cranes and the 1601 Congress building had one crane. The underground parking garage of the Texas Capitol Mall had three cranes to cover the extensive three blocks of construction. Cranes are operated from cabs located at the very top of the machines. From these heights, the operators on the Capitol Complex Project site could see miles into the distance of Austin’s rapidly growing skyline.

Before sunrise each day, the project crane operators made the long climb up the tower crane ladders to the cabs high above. To reach the cabs, the operators climbed a series of ladders with landings every 20 feet. Crane ladders are enclosed within safety caging to protect the operators during their ascent and descent. The cranes on the Capitol Complex Project were tied to the buildings under construction at about 200 feet and work elevator platforms were also attached from the building to the crane. This allowed the crane operators to ride the construction elevators part of the way to the top. Even with this boost, the operators had a daily workout.

Working Safe and Smart

The loads that the cranes moved each day were based on scheduled material deliveries. The general superintendent for each construction area oversaw the material deliveries and what materials will be moved by the cranes. If a work crew needed to move a load onsite, they could schedule crane time via an app. Crane scheduling on a construction site is a precise exercise and includes the number of loads, or picks, that the cranes will move each day and the weight of each. The cranes on the Capitol Complex Project lifted between 12,000 to 15,000 pounds per load, so the safety protocols were stringent.

Each morning, the general contracting staff of the project and the trade foremen meet to review the day’s schedule to make sure that everyone understands and agrees with the construction activities planned. While cranes were onsite, this included the scheduled crane load pick-ups. The foremen shared this information with their work teams. With thousands of pounds of material flying over the site each day, this load information was critical to keeping everyone on the project site safe and the workflow productive. Every person assigned to work on the construction site must first attend several safety orientations. While the cranes were onsite, this included specific training on crane safety protocols.

To prepare a crane to fly a load of material across the construction site, spotters on the ground coordinated closely with the crane operators via radio and hand signals to manage every step of the crane pick. The spotter first made sure that the flight path of the material load was clear of workers. Once the crane hook was securely attached to the load, the spotter blew a whistle which signaled to everyone on the construction site to look up and be aware. The spotter then let the operator know that the load could be moved. If the load was moving to the top of a building under construction, another spotter stood at the drop-off point and took over guiding the load as it approached the building.

Crane operators and spotters must have complete trust and respect for each other. This trust is critical during crane flights that transport loads across buildings where the operators have no line of sight and are completely dependent on the spotters to watch the loads and provide direction. With six tower cranes on the same construction site and swing radiuses that crossed paths, it was very important for the crane operators on the Capitol Complex Project to also maintain contact with each other.

While the crane operators moved materials around the site, they also served as the eyes in the sky for the project. On construction sites, weather conditions are constantly monitored, and from their high perches, crane operators can see approaching storms miles away. The crane operators on the project were responsible for their cranes at all times and could shut the machines down whenever they felt conditions were not safe, such as high winds or an approaching storm.

Hundreds of People Working as a Team

The cranes on the Capitol Complex project were essential to moving the heavy material loads quickly and efficiently. The cranes supported the work of the multiple general contractors and trades working on the site and kept the project moving forward.

Watching the 1801 Congress and 1601 Congress buildings rise from the ground seems almost magical, but it is the expertise, commitment, and daily collaboration of the men and women of the Capitol Complex construction teams that are making this legacy project a reality. We gratefully salute the efforts of all our construction partners!